Use Safe Materials

Fabric

Follow the guidance on the page for choosing safe fabric to make sure your carrier is made out of a fabric that can withstand the strain of babywearing.

Thread

When in doubt, use a good quality, 100% polyester, all-purpose thread. Avoid using “heavy duty” thread unless you have a lot of experience sewing with it and an industrial machine that can handle it. For most babywearing purposes, if you follow safe construction guidelines and secure straps with appropriate X boxes, then using all purpose thread should yield a carrier strong enough for most babywearing purposes up through as long as you will want to wear your child.

Cotton thread is fine for hems, but typically not recommended for weight-bearing seams or X boxes.

Rings

Use only weight-rated rings specifically designed for babywearing, and source them from a reputable seller that tests their rings for both strength and safe materials. In the USA, the general recommendation is to use rings from SlingRings.com. Outside the USA, RingsForBabySlings.co.uk is a great source.

Buckles & Ladder Locks

Make sure all buckles and ladder locks have a weight rating well above (preferably at least double) what weight you plan on using them for. (If you are hoping to wear your child up to approximately 40lbs, look for buckles rated to at least 80lbs.) Outdoor supply stores are often good sources. Buckles and ladder locks are the component most likely to fail on a carrier – source responsibly!

Webbing

Webbing can be made from many materials. Nylon, Polyester, and Polypropylene are all good options with slightly varying properties, with Nylon having slightly more stretch and the most strength, and polypropylene having the most water resistance and least stretch. Particularly with polypropylene, it is recommended to buy webbing that is weight tested well above the weight you plan on wearing, but typically webbing is rated to the hundreds or thousands of pounds and is very strong. Again, outdoor supply stores can be good sources.

Fabric can also be sewn into a tube or folded like bias tape and sewn flat to create “webbing” as well. Make sure to use fabric that is appropriate for weight bearing, and prioritize fabric with a particularly tight weave so as to avoid pulls and thread shifting as the fabric runs over the “teeth” of the buckles, and examine the fabric regularly for wear or thinning.

Padding

There are several options to add padding to structured carrier straps.

Quilt batting

Flat sheets of cotton or polyester fluff designed to go inside the layers of a quilt. This is easy to sew through, and adds just a minimal amount of cush and structure. Nice for areas where you want just a little bit of shaping and structure without needing much cush or bulk, such as for Soft Structured Carrier waistbands.

Fleece

Dense, fluffy polyester “fleece” (not actual wool) can be used in a single layer or multiple layers for padding. It provides a lot of dense cushion, especially for rings or buckles to keep them from digging in through a strap, but it also quite difficult to sew through. It is typically inexpensive, though.

Open Cell Foam

Open cell foam is the kind of squishy padding often used for chairs and stools. 1 inch dense open cell foam is typically a good choice for soft structured carrier shoulder straps, as well as more heavily structured waist bands. Despite its thickness, it is easier to sew through than fleece. Use something rigid and flat, like a pair of metal rulers, to press down the foam on either side of the foot to feed it through your sewing machine.

Closed Cell Foam

Closed cell foam is very dense – the type of foam used for yoga mats. This type of foam is popular for water carriers (since it doesn’t absorb as much water as open cell foam) and for situations where you want the carrier to not take up too much space but still have more structure than quilt batting or fleece would offer.

Attaching Components Securely

Ring Sling Shoulders

Different styles of ring sling shoulders are folded or pleated in different ways, but in general they are all similar in that the fabric is simply folded through the rings and then sewn down to keep the rings from sliding out.

The gold standard for securing a ring sling shoulder is to use 3 parallel lines of stitching, sewn with 100% polyester all purpose thread. Decorative stitches can be used, although generally 2 of the lines of stitching should just be straight stitches (or a regular zigzag stitch, if your fabric has any sort of width-wise stretch.)

You can fold a few inches of fabric through the rings, so the stitches are only 3 to 5 inches from the rings, or you can fold about 12 inches of fabric through the rings so the stitches are 12 inches away from the rings. This is referred to as a “floating” shoulder and it creates a double layer of fabric over the shoulder and places the stitches along the wearer’s back instead of at their collarbone.

The raw edge of fabric folded under for the shoulder needs to be finished in some way to prevent fraying, but this can be a double folded hem, a serged/overlocked edge, or as simple as a zigzag stitch run across the raw edge.

Seaming a Woven Wrap

It is safe to create a long woven wrap out of two shorter pieces of fabric, assuming the two pieces are from the same piece of fabric (such as two halves of a tablecloth.) You don’t want to seam together two fabrics of different fiber content, weaves, densities or ages as the fabrics could pull apart at the seam. It is also never recommended to seam together stretchy wraps.

To seam a woven wrap, you can use one of a few different methods:

X Boxes for Straps

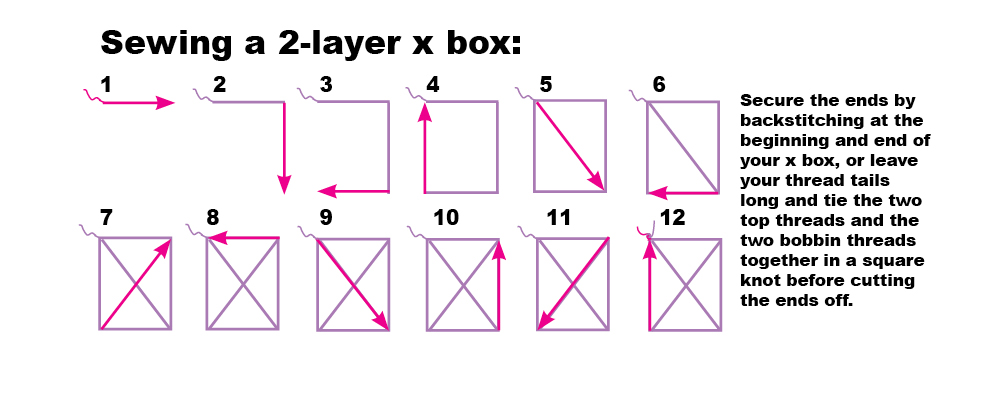

Most structured carriers are comprised of a vaguely rectangular body panel with straps attached to the corners – whether those straps are long wrap straps, short padded straps with buckles, or the loops of a traditional onbuhimo. These straps are under a lot of strain, and need to be reinforced against strain in all directions. The best way to do this is with an “x box” – a rectangle with an X across the middle, sewn in one continuous line.

Most structured carriers are comprised of a vaguely rectangular body panel with straps attached to the corners – whether those straps are long wrap straps, short padded straps with buckles, or the loops of a traditional onbuhimo. These straps are under a lot of strain, and need to be reinforced against strain in all directions. The best way to do this is with an “x box” – a rectangle with an X across the middle, sewn in one continuous line.

You can backstitch at the beginning and end of the x box, or leave the threads long and tie the two top threads together in a double knot, and the two bobbin thread ends together in a double knot, and then trim the ends.

You can sew the straps to a strong, densely woven piece of fabric that will then be sandwiched between two other pieces of fabric (one of which can be lightweight and decorative) to ensure your x boxes are hidden in the finished piece, or you can sandwich the strap between two strong body panel layers and x-box through the whole carrier (a good option for full wrap conversion carriers.)

If you need a visual on the difference between constructing a 2-layer body panel with exposed x boxes versus a 3-layer body panel with hidden x boxes, check out this brief tutorial: 2layer_vs_3layer

Finishing Edges

Double Folded Hems

Mitered Corners

When and When Not to Serge